New synthetic methods derived from solvothermal approach, such as ionothermal processes have been used to obtain nanopowders of LiMPO4 (M= Mn, Co and Ni), LixMSiO4 [Nytén, A. et al. (2005)] and Li and Na fluorophosphates battery materials [DiSalvo, F.J. et al.

(1971); Ellis, B.L. et al. (2007b)] using low heating temperature. Ionothermal synthesis has emerged when a great amount of research work is aimed at new low-cost processes to make highly electrochemically optimized electrode materials. This alternative route is considered as a new low cost synthesis process because it demands much less energy than high temperature ceramic routes. In spite of the higher cost of ionic liquids compared to water, it has been proved that these solvents can be reused without purification when used to prepare the same material, what leads to a significant cost decrease and minimizes waste production [Tarascon, J-M. et al. (2010)]. Ionothermal synthesis has also been carried out successfully by using microwave rather than traditional heating, which reduces reaction time and required energy for the synthesis.

Ionothermal synthesis is based on the use of an ionic liquid as reacting medium instead of water in solvothermal conditions. Ionic liquids are a class of organic solvents with high polarity and a preorganized solvent structure [Del Popolo, M. G. and Voth, G. A. (2004)]. Room temperature (or near-room-temperature) ionic liquids are classically defined as liquids at ambient temperatures (or <100 °C) that are made of organic cations and anions.

They have excellent solvating properties, little measurable vapor pressure, and high thermal stability. Solvating properties and fusion temperatures will depend on the combination of cations and anions chosen. In the area of materials science, there have been several reports of ionic liquids being used as solvents with very little or controlled amounts of water involved in the synthesis [Antonietti, M et al. (2004)]. Most of these studies concentrated on amorphous materials and nanomaterials.

Like water, ionic liquids resulting from compatible cationic/anionic pairs have excellent solvent properties. In addition, they possess high thermal stability and negligible volatility so the use of autoclave is not mandatory. Moreover, because of the flexible nature of the cationic/anionic pairs, they present, as solvents, great opportunities to purposely direct nucleation. Over the past decade, ionothermal synthesis has developed into an advantageous synthetic technique for the preparation of zeotypes [Lin, Z-J. et al. (2008)] and other porous materials such as metal organic framework compounds (MOFs), but there has been very limited use made of this technique in the synthesis of inorganic compounds.

The unique feature of ionothermal synthesis is that the ionic liquid acts as both the solvent and the template provider. Many ionic liquid cations are chemically very similar to species that are already known as good templates (alkylimidazolium-based, pyridinium-based ionic liquids). Many are relatively polar solvents, making them suitable for the dissolution of the inorganic components required for the synthesis. One of the defining properties of ionic liquids is their lack of a detectable vapor pressure which effectively results in the elimination of the safety concerns associated with high hydrothermal pressures and has also led to their use in microwave synthesis.

In the process of ionothermal route, since there are no other solvents added to the reaction mixture, the theory holds that no other molecules are present to act as space fillers during the synthesis. This means that ionothermal method ideally removes the competition between template–framework and solvent–framework interactions that are present in hydrothermal preparations. This, however, is the idealistic scenario, which is not always attainable due to the possible decomposition of a small fraction of the ionic liquid cations, resulting in smaller template cations which may preferentially act as the structure directing agent in the ionic liquid solvent [Parnham, E. R. and Morris, R. E. (2006)].

Recent molecular modeling studies indicate that the structures of ionic liquids are characterized by long range correlations and distributions that reflect the asymmetric structures of the cations. Long-range asymmetric effects of this kind potentially increase the likelihood of transferring chemical information from the template cation to the framework, a situation that is desirable if full control over the templating process is to be achieved [Parnham, E.R. and Morris, R.E. (2007)].

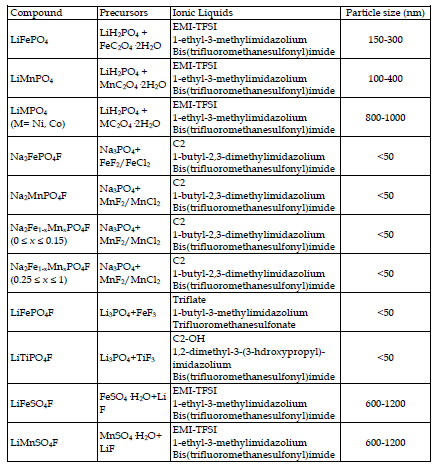

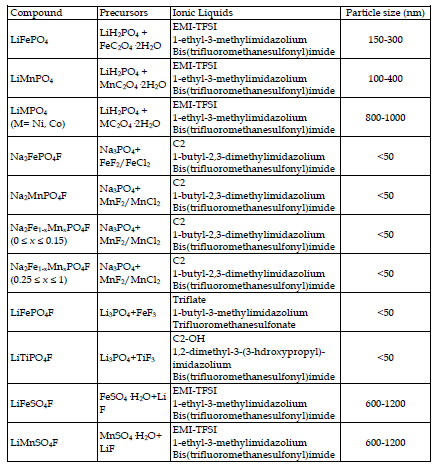

Tarascon et al. were the first to apply ionothermal synthesis to battery electrode materials. They tested several ionic liquids based on different cationic and anionic species as reacting medium for the preparation of LiFePO4 phase [Recham, N. et al. (2009a)]. The ionic liquids used demonstrated to have an impact on LiFePO4 nucleation/growth and to behave as a structural directing agent. For example, the use of a CN functionalized EMI-TFSI ionic liquid [1-ethyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide] produced needle-like powders along [010] direction that perfectly piled up to form a larger needle. This change on the ending group modified the polar character of the reacting medium and its solvating properties, thus, influencing crystal growth. Platelet-like particles along [020] direction were created by decreasing the polarity via the use of a C18-based EMI cation. Formation of these

two morphological kinds can be explained in terms of competing energy surfaces, and it is directly connected with the nature of the ionic liquid, solvating power, polarity and aptitude to specifically absorb on one of the surfaces. Depending on the ionic liquid properties,surface energy minimization of the system will take place via a different mechanism. All LiFePO4 produced materials were electrochemically active, but those with the best performance were of 300 and 500 nm size, showing 150 mAh·g-1 specific capacity at C/10 without carbon coating.

Ionothermal process was extended to the synthesis of size-controlled Na-based fluorophosphates [Na2MPO4F (M= Fe, Mn)] [Recham, N. et al. (2009b)]. These phases are attractive electrode materials because they are based on economic metals and can be used in both Li- and Na-based batteries. Furthermore, the fluorides possess higher electronegativity which increases the ionicity of the bonds and, thus, their redox potentials due to inductive effect. Nanosized samples of Na2FePO4F and Na2MnPO4F of about 25 nm diameter were prepared in a 1,2-dimethyl-3-butylimidazolium bis(trifluoromethanesulfonyl imide) ionic liquid, in contrast with coarse powders obtained by ceramic method. Electrochemical performance of the iron compound reached better results than that of ceramic material, with 115 mAh·g-1, better initial capacity, lower irreversible capacity, lower polarization and better capacity retention. Manganese phase did not show electrochemical activity, which follows the general tendency of Mn-based compounds having worse electrochemical performance than their Fe counterpart, for example in LiMPO4 and Li2MSiO4 families. There are two factors related to this phenomenon. First, the strong Jahn-Teller distortion on Mn3+, that affects its coordination sphere; and, second, the poor electronic-ionic conductivity of the materials, owing to the greater ionicity of the M-O bonding.

Ionothermal process has been successfully used for preparing new electroactive materials that had not been achieved before, such as LiFeSO4F. This material possesses an adequate structure to favor Li ions migration along channels. This electroactive phase had not been synthesized before because it is not accessible, neither by ceramic process nor in water medium. It decomposes at temperatures beyond 375º C and in water medium. This new cathode material showed electrochemical activity at 3.6 V, and a reversible specific capacity of 140 mAh·g-1, very close to theoretical specific capacity vale of 151 mAh·g-1. Thus, this preparative process has demonstrated to be a useful tool to synthesize nanosized new and known electroactive materials.